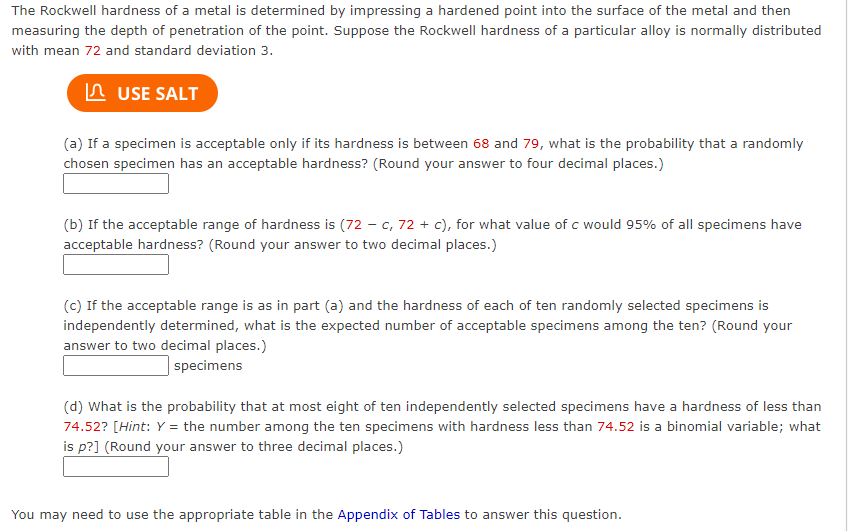

PDF) Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial Hardness, Knoop Hardness, and Scleroscope Hardness 1 | Aditya Yahya - Academia.edu

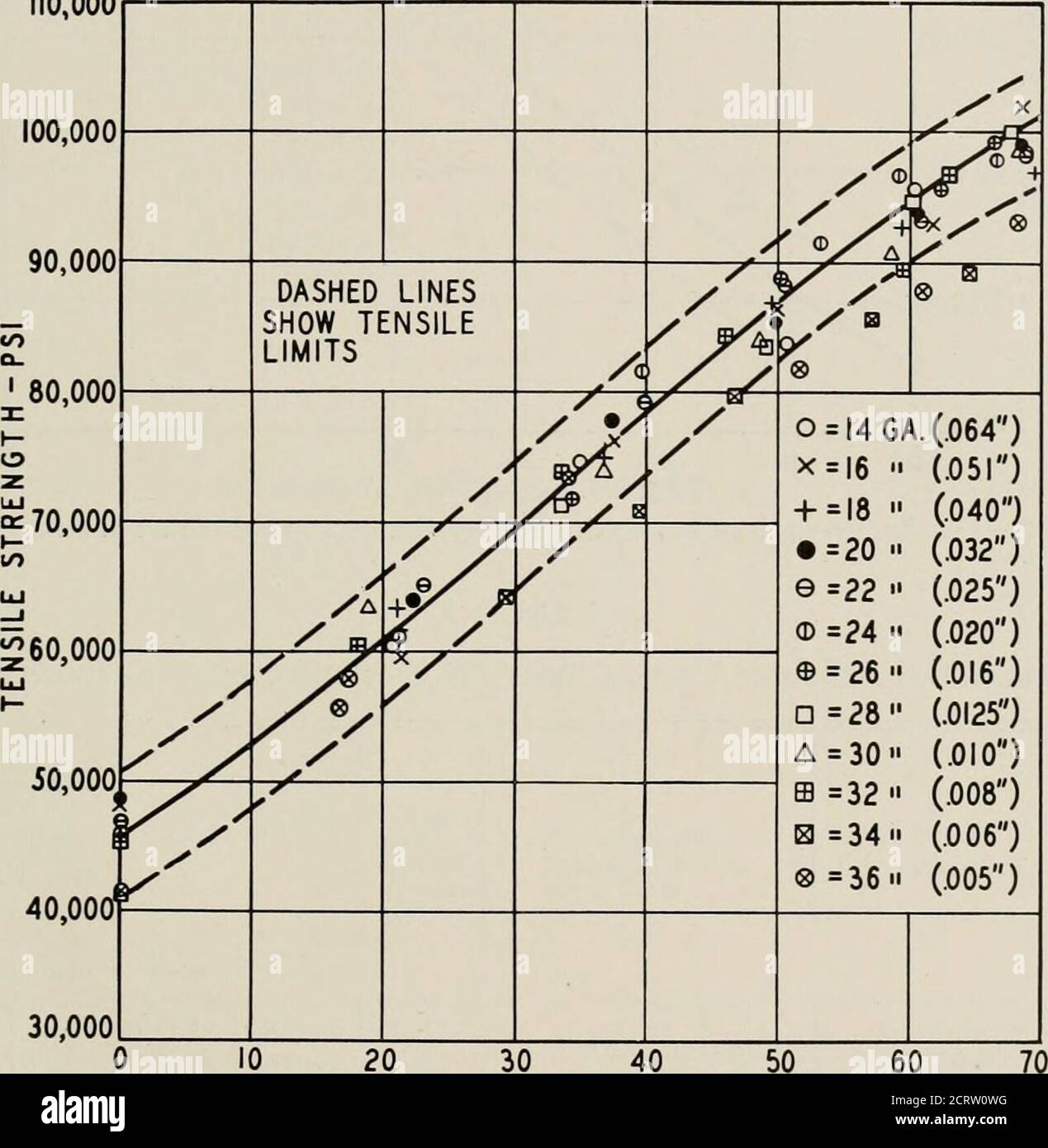

The Bell System technical journal . -I® 40,000 50,000 60,000 70,000 80,000 90,000TENSILE STRENGTH - PSI 100,000 110,000 Fig. 8—Relation of Rockwell Hardness to Tensile Strength of Alloy G Brass Rolling

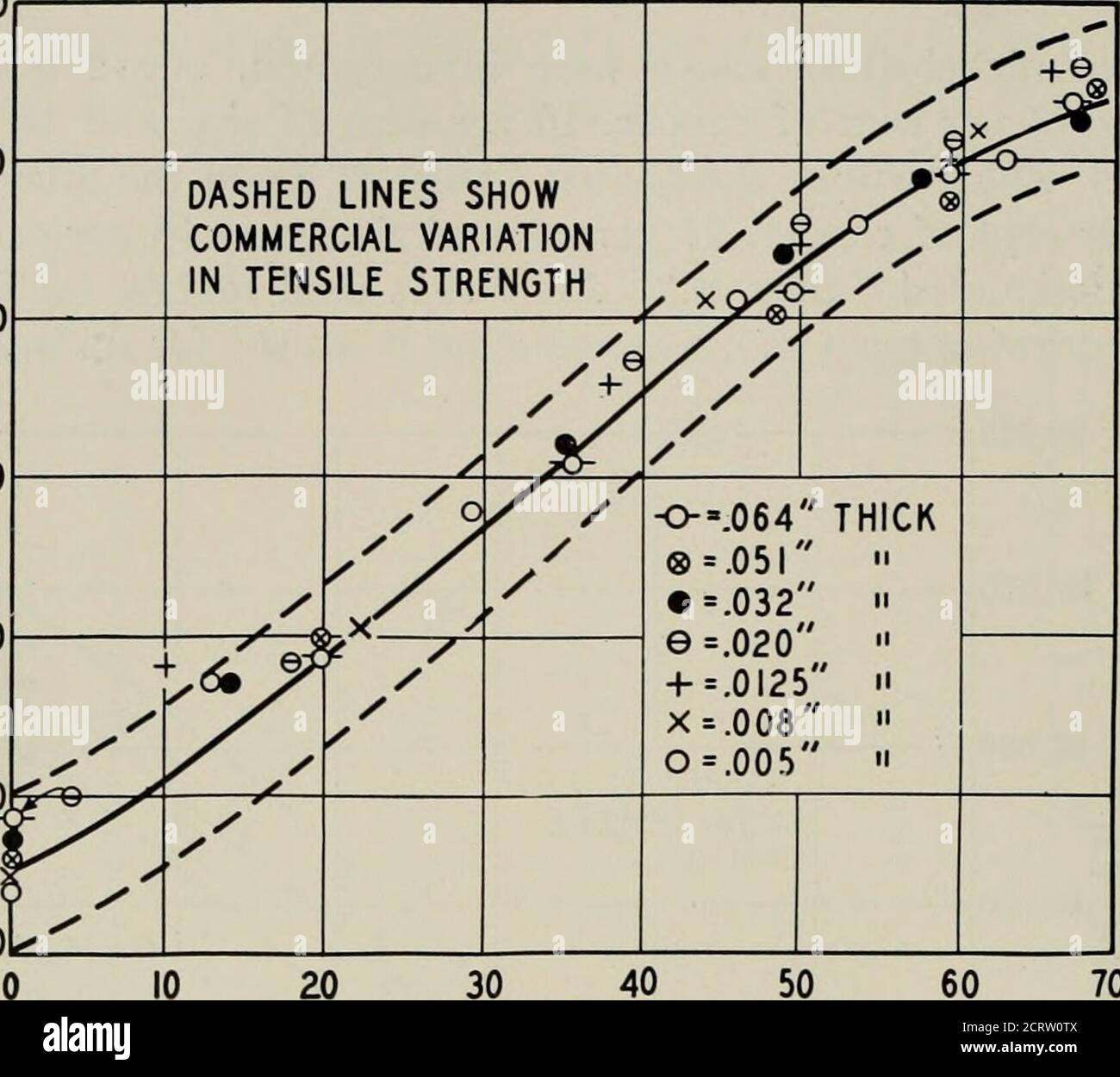

The Bell System technical journal . 30,000 10 20 30 40 50 PERCENT REDUCTION BY ROLLING Fig, 9—-Relation of Tensile Strength to Percentage of Reduction by Rolling ofAlloy G Brass Rolling

United Test HBRV-187.5 Motorized Brinell Rockwell & Vickers Hardness Tester, Universal durometer - Beijing United Test Co., Ltd. - PDF Catalogs | Technical Documentation | Brochure

Comparison of the Rockwell F Hardness ( HR F ) of various alloys in the... | Download Scientific Diagram

![Hardness test methods [SubsTech] Hardness test methods [SubsTech]](https://www.substech.com/dokuwiki/lib/exe/fetch.php?w=&h=&cache=cache&media=rockwell_b.png)